Web Menu

Product Search

Exit Menu

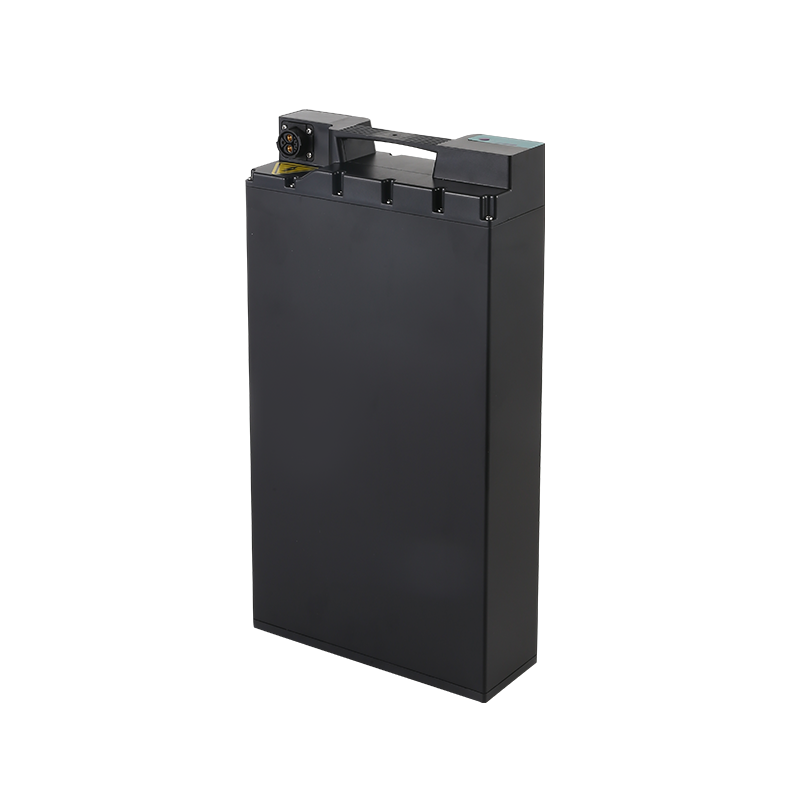

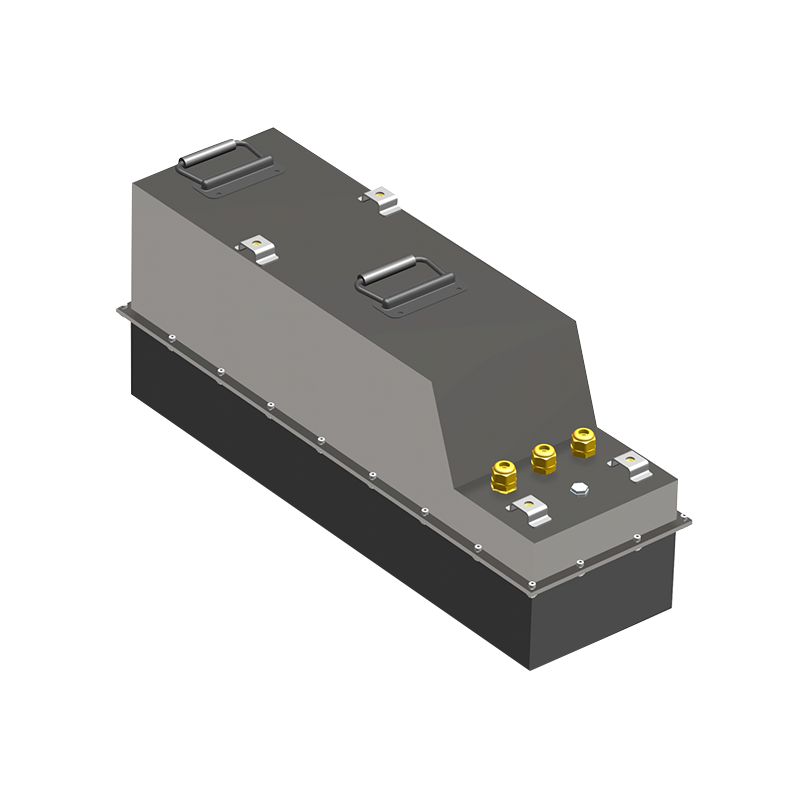

High Quality Lithium Ion Battery Defines Performance Standards

Across the spectrum of portable electronics, electric vehicles, and stationary energy storage, the demand for reliable and high-performing energy solutions has solidified the importance of the high quality lithium ion battery. This designation goes beyond basic functionality, representing batteries that meet rigorous standards for energy density, cycle life, safety, and consistency. As end-users and manufacturers become more discerning, the attributes defining a high quality lithium ion battery are becoming critical differentiators in a competitive and expanding global market.

The foundation of a high quality lithium ion battery lies in its core materials and cell engineering. It begins with the selection and precise formulation of active materials for the cathode and anode. Consistent particle size, high purity, and advanced coatings contribute directly to the stability and capacity of a high quality lithium ion battery. The electrolyte composition, the separator's integrity and porosity, and the precision of the cell assembly process are all meticulously controlled. These factors collectively influence key performance metrics, such as the ability to retain capacity over hundreds of charge-discharge cycles and deliver stable voltage under load.

Performance and longevity are the many tangible benefits of a high quality lithium ion battery. A well-engineered cell offers higher energy density, meaning it can store more energy in a smaller, lighter package—a crucial factor for mobile devices and electric vehicles seeking to improve range. Furthermore, a high quality lithium ion battery is characterized by a low rate of capacity fade. It can withstand a high number of complete charge and discharge cycles while retaining a significant percentage of its original capacity, providing greater long-term value and reducing the frequency of replacement. This durability is a direct result of predominant materials and manufacturing that less parasitic reactions within the cell.

Safety is an non-negotiable pillar for any product that can be classified as a high quality lithium ion battery. This encompasses both intrinsic safety through stable cell chemistry and engineered safety through protective features. Robust internal separators that resist shrinkage and puncture, stable electrolyte additives that reduce flammability, and precise manufacturing that eliminates microscopic metallic particles are all hallmarks of a high quality lithium ion battery. Externally, Battery Management Systems are integral, actively monitoring temperature, voltage, and current to prevent operations outside safe parameters, thereby protecting both the battery and the end-user.

The manufacturing environment plays a decisive role in producing a high quality lithium ion battery. Production under strict humidity and temperature control, with automated processes that less human error and contamination, is essential. Extensive testing protocols, including formation cycling, aging tests, and safety stress tests, are applied to validate performance and weed out potential defects before a high quality lithium ion battery reaches the market. This commitment to process control is what separates consistent, reliable products from lower-tier alternatives.

The definition of a high quality lithium ion battery will continue to evolve with technology. Research into new cathode and anode materials, solid-state electrolytes, and more sustainable production methods will set new benchmarks. However, the core principles of rigorous material science, precision engineering, and comprehensive safety will remain the unchanging foundation. As the world's reliance on portable and stored energy deepens, the value and necessity of the truly high quality lithium ion battery will only become more pronounced.

-

+86-13049701086

-

Stonehuang@CGONEN.com

-

No.88, Huji Road, Taizhou Bay Binhai New Area, Jiaojiang District, Taizhou City, Zhejiang Province, China