Web Menu

Product Search

Exit Menu

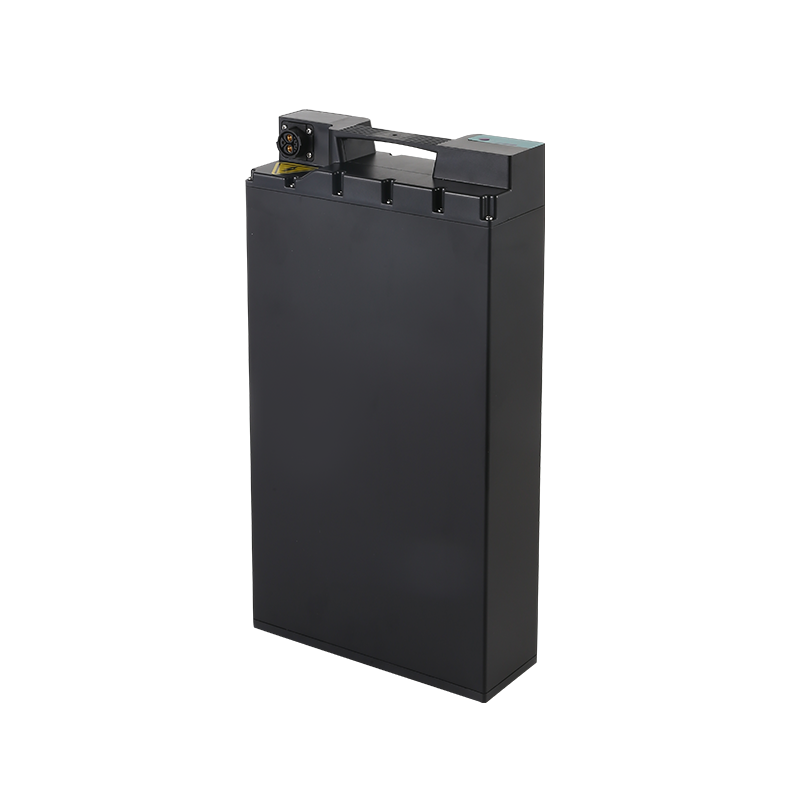

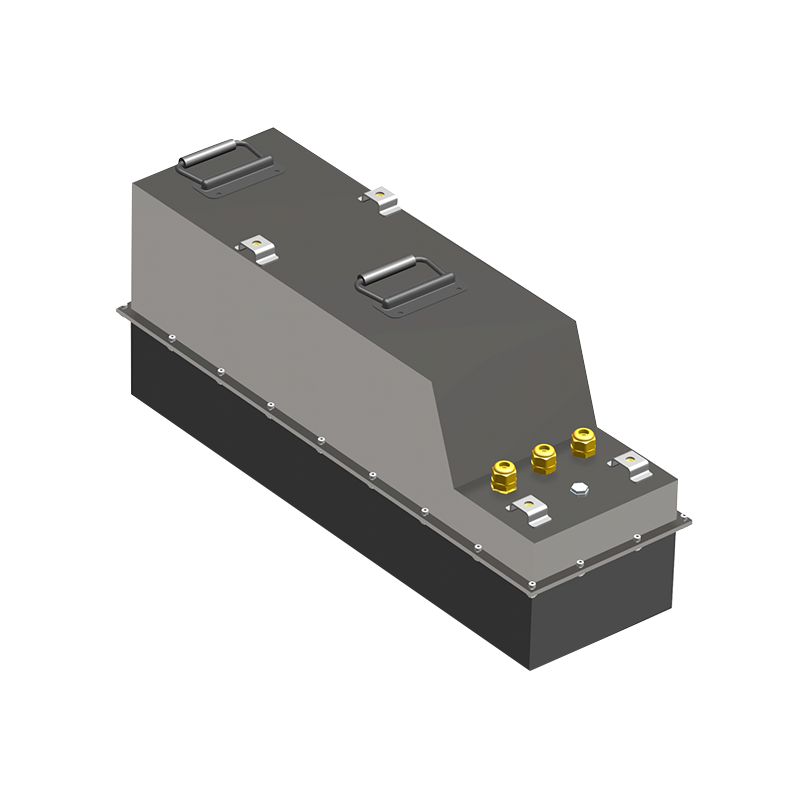

The Innovation of Cylindrical Cell Modules

Sale Cylindrical Cell Module Manufacturing Supplier Maker

Cylindrical cell modules are a type of battery cell configuration that has gained significant attention in the field of energy storage. These modules are characterized by their cylindrical shape and are widely used in various applications due to their versatility and performance.

Cylindrical cell modules are constructed with a cylindrical shape, which is different from other common battery cell designs such as prismatic or pouch cells. The cylindrical design offers several benefits, including structural integrity and ease of manufacturing. Inside the cylindrical casing, there is typically a spirally wound electrode assembly. This assembly consists of a positive electrode, a negative electrode, and a separator that prevents direct contact between the electrodes, which could cause a short circuit.

The performance of cylindrical cell modules is largely determined by the materials used in their construction. Lithium-ion technology is commonly employed due to its high energy density and longevity. The positive electrode is often made from lithium cobalt oxide (LCO), lithium manganese oxide (LMO), or lithium nickel oxide (LNO), while the negative electrode is typically made from graphite or silicon. The electrolyte, which allows for the flow of lithium ions between the electrodes, is a crucial component and can be either liquid or solid-state.

The manufacturing of cylindrical cell modules involves a series of steps, including the preparation of the electrode materials, the assembly of the cell, and the final sealing process. The electrodes are coated onto a metal foil current collector, which is then wound into a spiral along with the separator. This assembly is inserted into a cylindrical can, and the cell is filled with electrolytes before being sealed. The sealing process is critical as it ensures that the cell is protected from external contaminants and maintains a stable internal environment.

Cylindrical cell modules offer several advantages that make them a popular choice for various applications:

Safety: The cylindrical shape provides a robust mechanical structure that can withstand physical stress without compromising the integrity of the cell.

Thermal Management: The cylindrical design allows for efficient heat dissipation, which is crucial for maintaining the cell's performance and longevity.

Scalability: Cylindrical cells can be easily scaled up or down to meet the energy requirements of different applications.

Customization: The cylindrical form factor allows for a high degree of customization in terms of size and capacity, making it suitable for a wide range of uses.

Cylindrical cell modules are used in a variety of applications, including:

Consumer Electronics: They power devices such as laptops, smartphones, and digital cameras.

Electric Vehicles (EVs): Cylindrical cells are a common choice for EV batteries due to their high energy density and robustness.

Energy Storage Systems (ESS): They are used in grid-scale storage systems to balance energy supply and demand.

Portable Power: Cylindrical cells are found in portable power banks and other mobile energy solutions.

Despite their many advantages, cylindrical cell modules also face challenges, such as the need for improved energy density and cost reduction. Research and development in materials science and manufacturing techniques are ongoing to address these issues.

Cylindrical cell modules play a significant role in the energy storage industry, offering a reliable and efficient solution for a multitude of applications. The ongoing innovation in cylindrical cell technology is a testament to the dynamic nature of the energy storage sector and the potential it holds for growth and improvement.

-

+86-13049701086

-

Stonehuang@CGONEN.com

-

No.88, Huji Road, Taizhou Bay Binhai New Area, Jiaojiang District, Taizhou City, Zhejiang Province, China